In the high-stakes world of Abu Dhabi’s oil, gas, and petrochemical sectors, safety is not merely a priority—it is the absolute foundation of all operations. At the core of this safety culture are Zone 2 installation services, a highly specialized and critical field dedicated to modifying and certifying equipment for safe use in hazardous environments. This comprehensive guide details the what, why, and how of these services, highlighting their crucial role in ensuring compliance with the stringent guidelines set forth by the Abu Dhabi National Oil Company (ADNOC).

Understanding the Zone 2 Classification

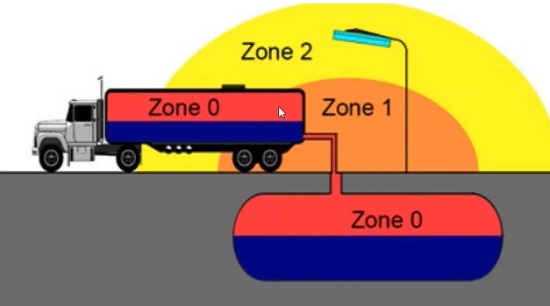

To fully grasp the importance of these services, one must first understand what a “Zone 2” area is. As defined by international standards (like IEC 60079-10-1), a hazardous area is a place where flammable gases, vapors, or mists are present in quantities sufficient to produce an explosive mixture. These areas are classified into three zones based on the probability of the hazardous atmosphere being present:

● Zone 0: An area where an explosive atmosphere is present continuously or for long periods.

● Zone 1: An area where an explosive atmosphere is likely to occur in normal operation.

● Zone 2: An area where an explosive atmosphere is not likely to occur in normal operation. If it does occur, it will only exist for a short period.

The distinction is critical. While the risk in a Zone 2 area is lower than in Zone 0 or 1, the potential for a catastrophic event remains. Therefore, all equipment, from vehicles to electrical panels, must be engineered to eliminate any potential ignition sources, such as sparks from a battery or heat from an engine’s exhaust.

The Scope of Zone 2 Installation Services

Specialized companies in Abu Dhabi offer an end-to-end solution for Zone 2 compliance. Their services extend far beyond simple modifications; they involve a detailed engineering assessment, professional execution, and comprehensive certification. The services can be broadly categorized into two main areas:

1. Vehicle and Equipment Conversion:

This is one of the most visible and widely required services. Standard diesel- or petrol-powered vehicles and mobile machinery (e.g., cranes, generators, forklifts) are converted for safe operation in hazardous zones. The process involves multiple critical modifications:

● Engine Over-Speed Protection: The installation of a Chalwyn valve, a device that automatically shuts down the engine by cutting off the air supply if it detects an over-speed condition, which could indicate a gas leak.

● Exhaust System Modifications: A spark arrestor is fitted to the exhaust to capture and extinguish any incandescent particles before they can exit the system. This prevents ignition from hot exhaust gases.

● Electrical System Upgrades: The vehicle’s entire electrical system is overhauled. This includes fitting a flameproof battery isolator switch, sealing the alternator and starter motor, and using explosion-protected wiring and lighting.

● Static Discharge Prevention: Anti-static belts and specialized grounding systems are installed to dissipate any static electricity that could build up and cause a spark.

2. Electrical and Instrumentation (E&I) Systems:

Beyond mobile equipment, Zone 2 services also cover the installation and maintenance of fixed electrical systems within industrial facilities. This ensures the entire environment is protected.

● Explosion-Proof Enclosures: All electrical components, including junction boxes, control panels, and switches, are housed in certified, robust enclosures designed to contain any internal explosion and prevent it from propagating to the outside environment.

● Certified Lighting and Power: Lighting fixtures and power outlets are replaced with units that are rated for Zone 2 use. This often includes LED or fluorescent lighting that is sealed and protected against a hazardous atmosphere.

● Gas Detection and Alarm Systems: Installation of both fixed and portable gas detectors that continuously monitor the air for flammable gas concentrations and trigger an alarm if a dangerous level is reached.

The Crucial Role of ADNOC Guidelines and International Certifications

Simply modifying equipment is not enough. The ultimate goal of Zone 2 services is to achieve formal certification, which is where the role of regulatory bodies becomes paramount.

ADNOC, as the primary regulator of the oil and gas industry in Abu Dhabi, has established a set of detailed technical guidelines and standards that all operators and contractors must adhere to. A key part of a service provider’s role is to ensure that all installations not only meet but exceed these specific ADNOC requirements.

Furthermore, these local guidelines are typically aligned with global best practices and standards, most notably ATEX (the European directive on equipment for use in explosive atmospheres) and IECEx (the International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres). A Zone 2 certificate issued by a provider often references compliance with these international standards, providing a globally recognized benchmark of safety and quality.

The certification process is meticulous. It begins with a technical assessment of the equipment, followed by the actual modifications. The final step is a rigorous inspection and the issuance of a compliance certificate and a technical dossier, which is essential for official approval to operate within ADNOC-controlled areas.

The Broader Impact

The investment in Zone 2 installation services yields significant benefits far beyond mere regulatory compliance:

● Enhanced Safety: The most important benefit is the protection of human life. These services drastically reduce the risk of catastrophic accidents, safeguarding workers and the public.

● Asset Protection: A single incident can cause massive damage to expensive infrastructure. By preventing explosions, these services protect critical assets and ensure operational continuity.

● Operational Excellence: Compliance avoids costly operational shutdowns, fines, and legal penalties, allowing businesses to operate smoothly and maintain their license to operate.

● Reputation and Trust: Adhering to the highest safety standards builds a strong reputation, fostering trust with clients, partners, and the community.

In conclusion, Zone 2 installation services in Abu Dhabi are a vital component of the region’s industrial safety framework. They represent a blend of specialized engineering, strict adherence to regulations, and a commitment to protecting personnel and assets. For any company operating in or near hazardous zones, these services are not an option—they are a fundamental requirement for responsible and sustainable operation.